How To Build A Softwash Metering Valve

Are you tired of batch mixing your cleaning solutions for soft washing and roof washing projects? Say goodbye to the hassle and inefficiency with the SESW Batch Buster Softwash Metering Valve. In this comprehensive guide, we'll walk you through the process of building your very own blend manifold, also known as a proportioner. With the Batch Buster Valve, you can effortlessly blend sodium hypochlorite, water, and surfactant on the go, adjusting chemical ratios to suit different surfaces. Plus, stick around to learn how you can win a blend manifold worth $1100 from Southeast Softwash!

Why You Need a Blend Manifold

Blend manifolds, also known as proportioners, are essential tools for any soft washing or roof washing professional. These devices allow you to blend multiple solutions seamlessly, eliminating the need for batch mixing. With a blend manifold, you can adjust chemical ratios on the fly, ensuring optimal cleaning results and saving time and resources in the process.

Quality Components Make a Difference

While it may be tempting to use off-the-shelf hardware store parts to construct your blend manifold, investing in quality components is crucial for optimal performance. Without proper valves designed for metering and check valves to prevent cross-contamination, your system may experience issues such as air leaks and diluted solutions. Don't waste your time and money on inferior parts—follow our guide to ensure success the first time.

Step-by-Step Assembly Guide

Follow these steps to build your blend manifold:

-

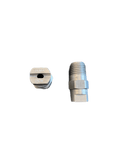

Start with a Machined Block: Begin with a machined block designed to accommodate the necessary fittings. This ensures sturdiness and reduces the risk of air leaks.

-

Apply Thread Sealant: Use a quality thread sealant to prevent leaks. Ensure thorough application without creating a messy workspace.

-

Incorporate Check Valves: Install check valves to prevent cross-contamination between solutions. Pay close attention to directional arrows for proper installation.

-

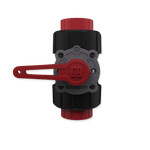

Integrate Batch Buster Valve: Incorporate the Batch Buster Valve for precise control over surfactant flow.

-

Finalize Valve Placement: Arrange valves for easy operation and accessibility, ensuring proper flow direction for optimal performance.

-

Install Hose Barbs: Attach hose barbs for connecting bleach, water, and surfactant lines. Choose appropriate sizes for efficient fluid flow.

Optimizing Your Setup

Position the water supply furthest from the pump outlet to facilitate flushing with fresh water after cleaning. This helps prolong the life of system components and ensures thorough cleaning results.

Win Your Own Blend Manifold

Subscribe to the channel, like the video, and leave a comment mentioning southeastsoftwash.com to enter the giveaway. Don't miss your chance to win a blend manifold worth $1100 from Southeast Softwash!

Conclusion

With the SESW Batch Buster Softwash Metering Valve and our expert guidance, you can take your soft washing and roof washing operations to new heights. Say goodbye to batch mixing and hello to precision blending on the go. Invest in quality components, follow our step-by-step assembly guide, and enter the giveaway for a chance to win your own blend manifold. Don't forget to check out how to wash for comprehensive training on exterior cleaning techniques. Get ready to elevate your cleaning game and achieve outstanding results with SESW!

Get this product

- Choosing a selection results in a full page refresh.

- Opens in a new window.